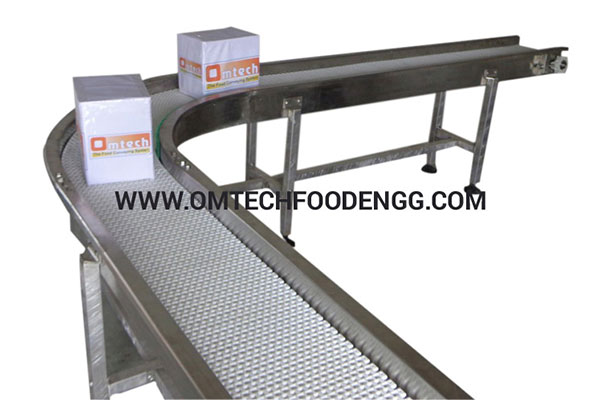

Inspection ConveyorBelt Manufacturer

As being leading manufacturer and supplier of high-tech conveying systems, we put forth an efficient series of precisely engineered Inspection Conveyor Belt used in varied functional operations.It is used for processing and packaging application. Inspection conveyor Belt manufacturer is specially built to sort out the products or materials with their quality and grade.Inspection Conveyor Belt commonly used to check out fruits and vegetables. Visual checking of these materials can be supported by specially designed belts with determined cleats and side walls. It can be also customized for the different attachments for specific product range as per their size and shapes.

Varied designed offered for quick, precise and suitable operation. In order to maintain hygiene, it can be offered with drain tray. It is easy to clean and maintain.We offer our client different types of conveyor belt as Food Conveyor Belt, activated roller belt technology,elevator conveying belt, food conveyor belt,High impact belts ,high temperature conveyor belting .

Our Inspection Conveyor Belt is widely appreciated by esteemed clients which are situated for industries such as Food industries.Our offered range is well checked by the quality inspector for faultless functionality,this Inspection Conveyor Belt is with rigid body, high tensile strength, weather resistance.Inspection Conveyor Belt is with changeable speed drive for varying speed of conveyor belt as per the product requirement Food quality with ergonomic design is for ease of operation for the workers.Our Inspection Conveyor Belt used in food processing industries for inspection , preparation and transportation of fruits and vegetables.This Inspection Conveyor Belt is for the food quality endless conveyor belt is for ergonomic design ensures ease of operation for the worker for easy movement of the food material, container, etc.

Features of Inspection Conveyor Belt :

- High capacity

- energy efficient

- reduce contamination risk

- convenient length options

- improved quality standards

- suitable for new material and products

- decrease downtime